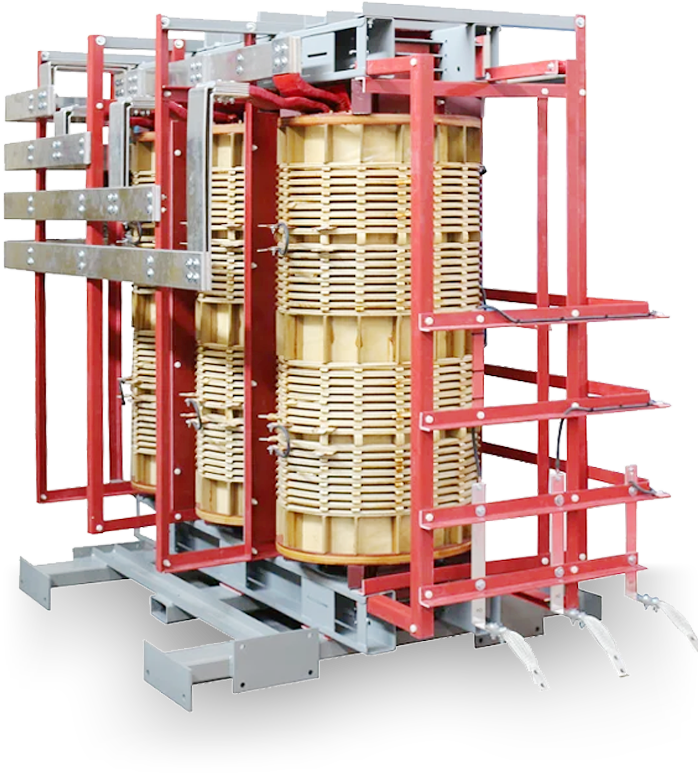

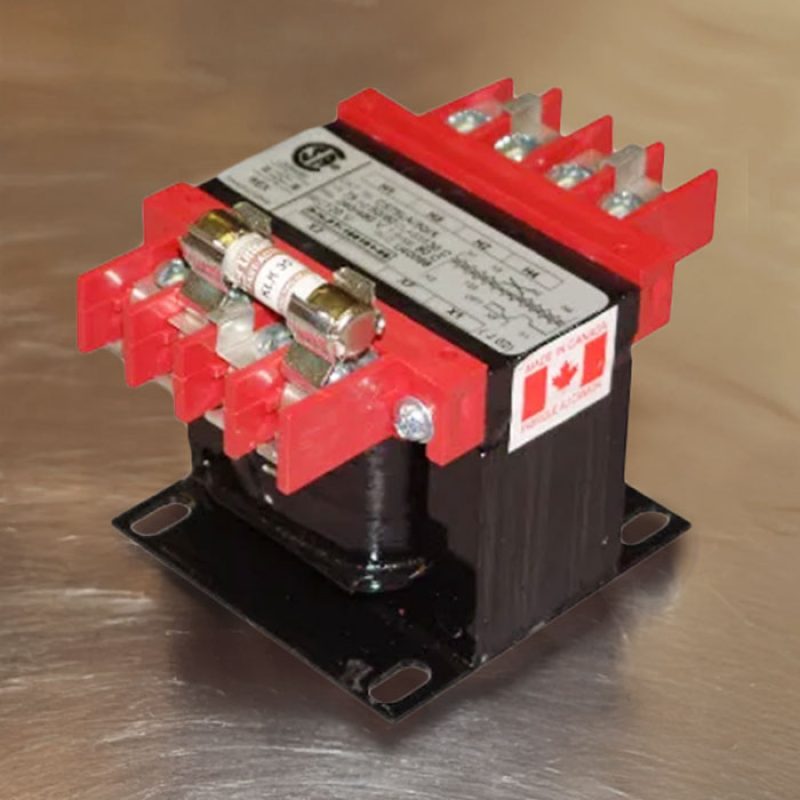

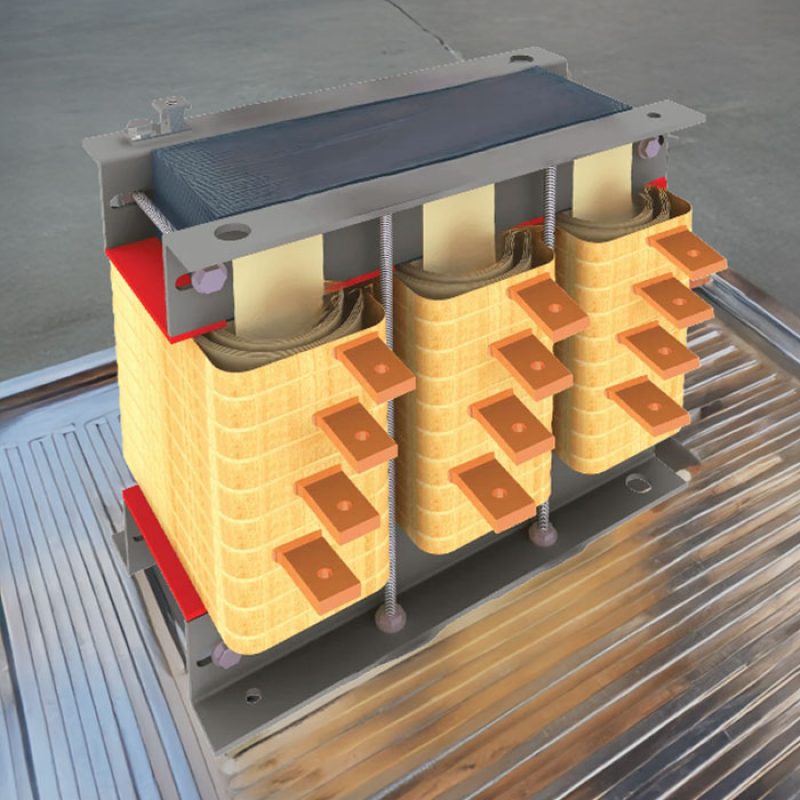

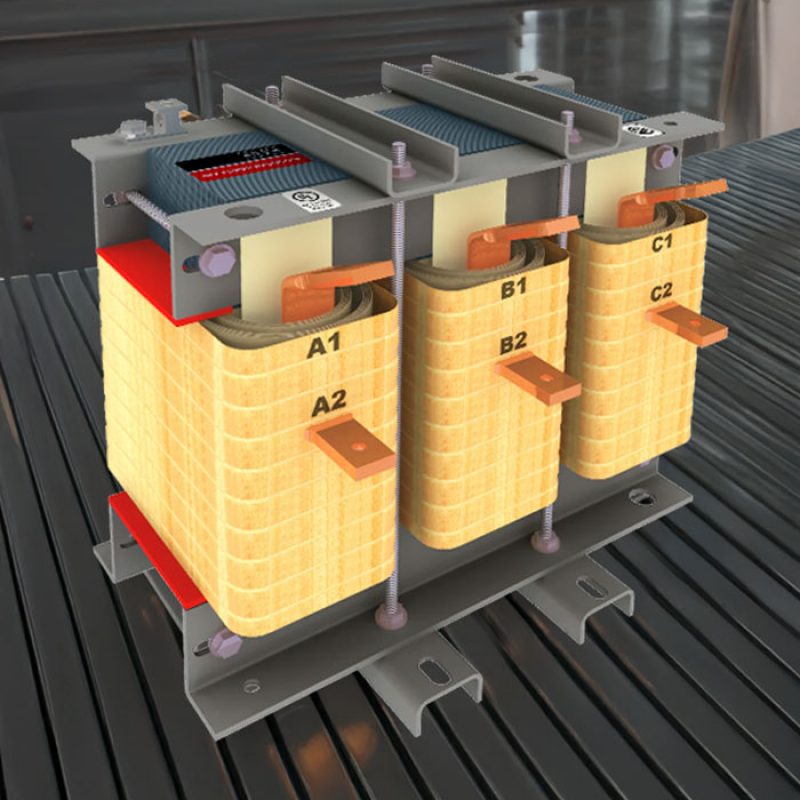

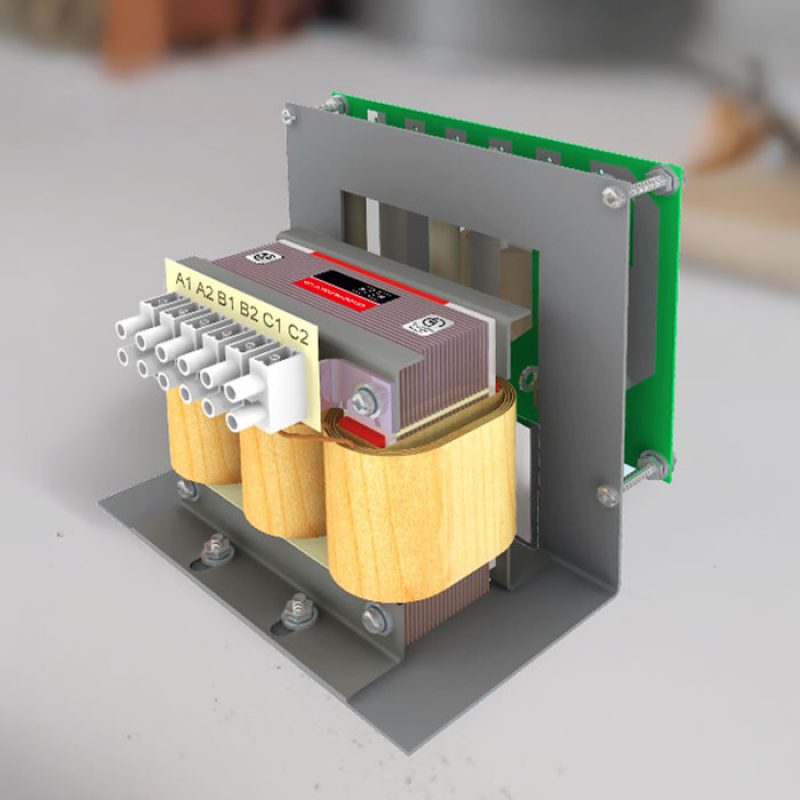

Henka’s VPI Power Transformers step down high voltages for industrial and utility applications. Vacuum pressure impregnation eliminates air voids, enhancing thermal conductivity and protection against contaminants. VPE models add extra epoxy layers for superior durability in harsh conditions.

Proudly Canadian

Edit Content

Power You

Can Count On

At Henka, we specialize in dependable transformers & UPS systems that help power industries across Canada and beyond. Our mission is simple: provide reliable, efficient, and high-performance transformers & UPS systems that businesses can count on.