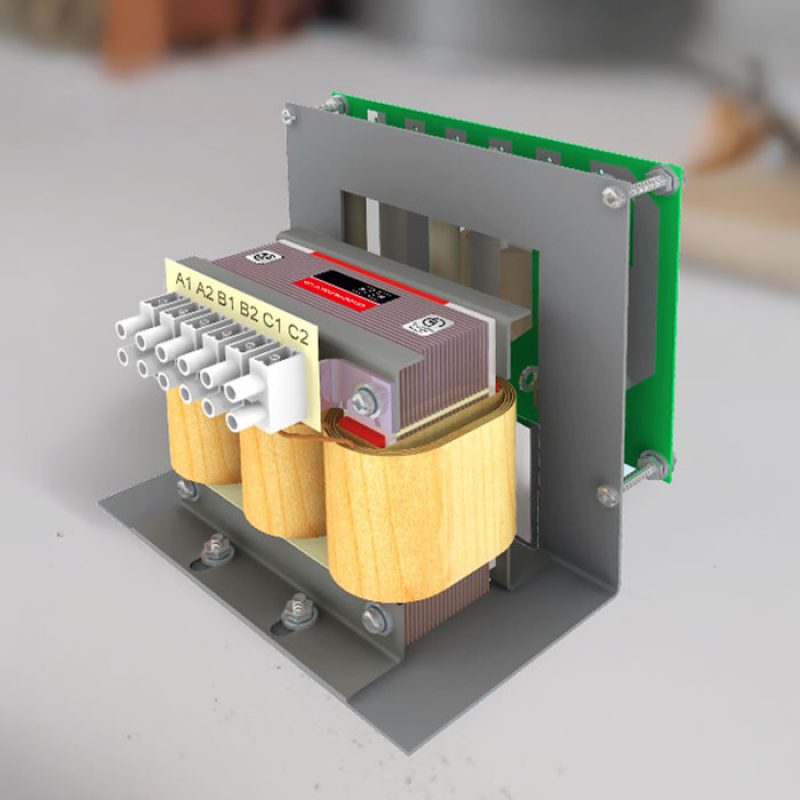

Selecting the right transformer is crucial for ensuring safe, efficient, and reliable power distribution. Whether for industrial, commercial, or utility applications, the right transformer minimizes energy losses, optimizes performance, and protects electrical equipment from power fluctuations. With various transformer types available—each designed for specific voltage levels, loads, and environments—it’s essential to understand key factors that influence the selection process.

At Henka Power, we provide high-quality transformers engineered for diverse applications, offering solutions that enhance power stability, reduce operational costs, and ensure compliance with industry standards. This guide will help you navigate the essential considerations when choosing the right transformer for your needs.

Understanding Voltage, Load, and Application Requirements

The first step in selecting a transformer is determining the voltage and load requirements of your electrical system. Transformers serve the critical function of adjusting voltage levels to ensure the safe and efficient operation of equipment. They either step up voltage for long-distance transmission or step down voltage for end-use applications.

- Step-Up Transformers increase voltage to minimize energy loss during transmission over long distances. These are essential for power generation facilities and grid systems.

- Step-Down Transformers reduce voltage to levels suitable for industrial, commercial, and residential applications, ensuring compatibility with electrical devices and machinery.

- Distribution Transformers provide final-stage voltage regulation in power grids, supporting local electrical distribution networks for commercial and industrial settings.

- Isolation Transformers provide electrical separation between circuits to prevent surges, eliminate ground loops, and protect sensitive equipment from electrical disturbances.

- Autotransformers use a single winding to adjust voltage with higher efficiency and cost-effectiveness, commonly used in industrial motor applications.

Understanding your voltage requirements ensures you select a transformer that matches your specific power distribution needs without overloading or underperforming.

Key Factors in Transformer Selection

1. Load Capacity and Power Rating

The load a transformer is expected to handle is one of the most critical factors in choosing the right unit. Transformers are rated in kVA (kilovolt-amperes), which indicates the amount of power they can safely deliver. Selecting a transformer with a power rating too low for your application can result in overheating and premature failure, while an oversized transformer may lead to unnecessary energy losses and higher costs.

Henka Power’s transformers are designed to accommodate varying load capacities, ensuring that businesses can optimize energy efficiency while maintaining system reliability. Our team can help assess your power requirements and recommend the right kVA rating for your operations.

2. Environmental Conditions

Where and how a transformer will be used greatly impacts its design and specifications. Environmental factors such as temperature, humidity, and exposure to contaminants must be considered to ensure durability and longevity.

- Indoor vs. Outdoor Use: Outdoor transformers require weatherproof enclosures and additional insulation to withstand environmental elements such as rain, snow, and extreme temperatures.

- High-Temperature Environments: Industrial facilities with excessive heat generation may require specialized cooling mechanisms or high-temperature insulation materials to prevent overheating.

- Corrosive or Hazardous Locations: Transformers used in chemical plants, marine environments, or areas with high moisture levels should have protective coatings and enclosures to resist corrosion and moisture damage.

Henka Power provides transformers with custom enclosures, enhanced insulation, and specialized materials to withstand harsh operating conditions.

3. Energy Efficiency and Loss Reduction

Transformers play a significant role in energy conservation, and choosing an energy-efficient model can lead to substantial cost savings. Transformer losses typically fall into two categories:

- Core Losses (No-Load Losses): These occur when the transformer is energized, even when not supplying a load.

- Copper Losses (Load Losses): These occur when the transformer is actively supplying a load and depend on the amount of current flowing through the windings.

Henka Power’s high-efficiency transformers are designed with low-loss core materials and optimized winding techniques to reduce energy waste. By investing in an energy-efficient transformer, businesses can lower operational expenses while meeting sustainability goals.

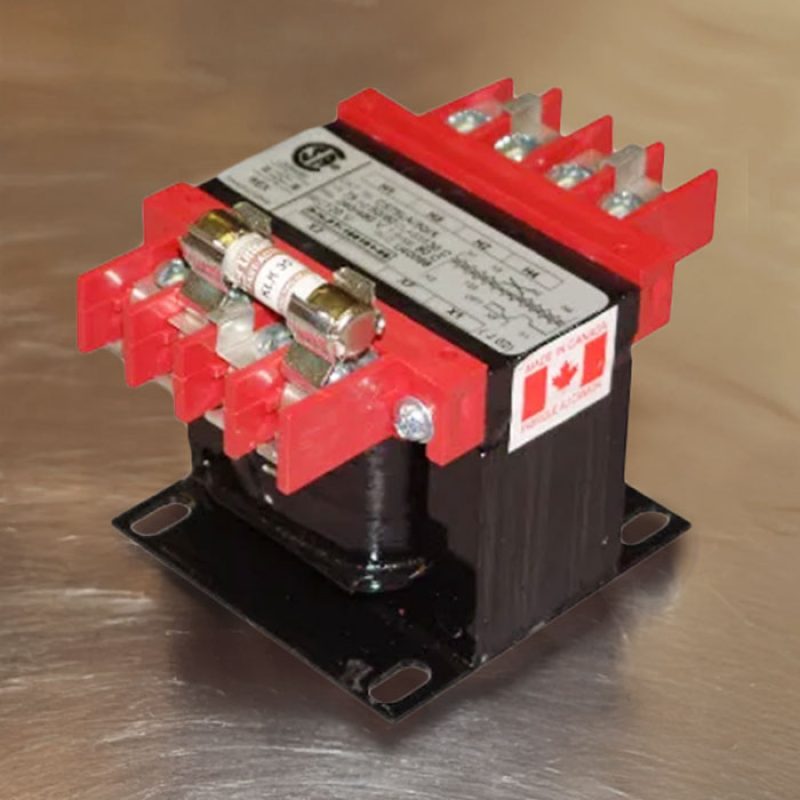

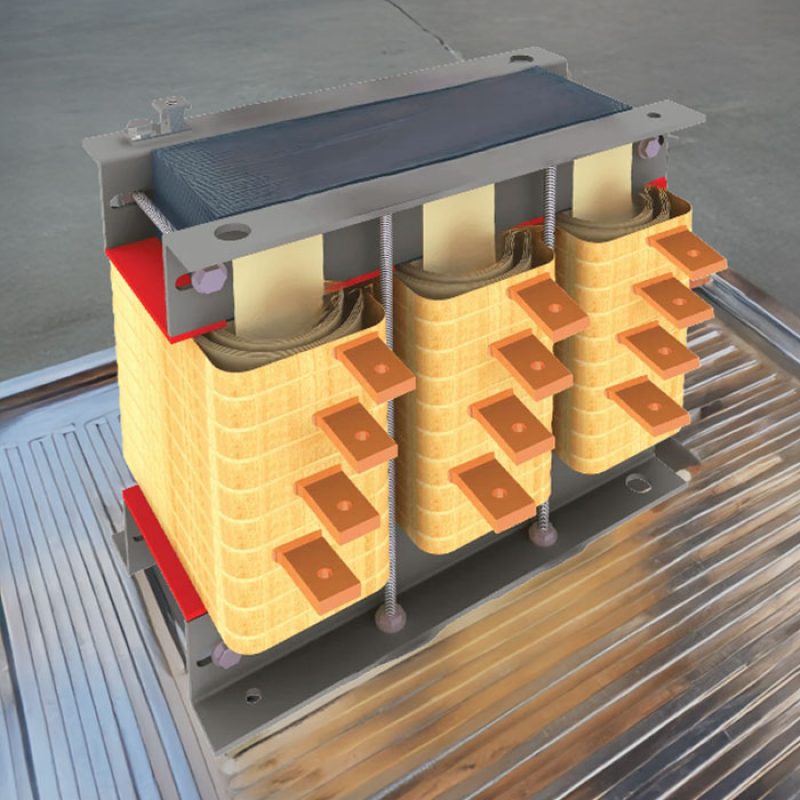

4. Cooling Methods

Transformers generate heat during operation, and efficient cooling is essential for maintaining performance and longevity. There are two main types of cooling methods:

- Dry-Type Transformers: Use air as a cooling medium and are ideal for indoor applications where fire safety and minimal maintenance are priorities.

- Oil-Filled Transformers: Use insulating oil for cooling and offer superior thermal performance, making them suitable for outdoor and high-capacity applications.

Choosing the right cooling method depends on the application, space constraints, and maintenance requirements. Henka Power provides both dry-type and oil-filled transformers, ensuring optimal solutions for every industry.

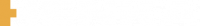

5. Compliance with Industry Standards

Selecting a transformer that meets or exceeds industry regulations is essential for safety, efficiency, and long-term reliability. Henka Power’s transformers are designed in compliance with industry standards, including:

- IEEE (Institute of Electrical and Electronics Engineers)

- NEMA (National Electrical Manufacturers Association)

- CSA (Canadian Standards Association)

- UL (Underwriters Laboratories)

By adhering to these stringent guidelines, Henka Power ensures that its transformers provide safe, high-performance power distribution in all environments.

Custom Solutions for Unique Applications

Every project has specific power requirements, and standard transformers may not always be the perfect fit. Henka Power specializes in designing and manufacturing custom-engineered transformers tailored to unique applications. Whether it’s a specialized transformer for medical imaging equipment, renewable energy integration, or mission-critical industrial operations, our team works closely with clients to develop solutions that maximize efficiency and reliability.

Some of our custom transformer capabilities include:

- Special voltage configurations to match specific power needs

- Enhanced insulation and cooling solutions for extreme conditions

- Compact and lightweight designs for space-constrained applications

- Harmonic mitigation features for cleaner power distribution

Why Choose Henka Power for Your Transformer Needs?

Henka Power is committed to delivering transformers that meet the highest standards of performance, durability, and efficiency. Our extensive experience in power distribution allows us to provide solutions that enhance operational stability and reduce long-term costs.

What Sets Henka Power Apart?

✅ High-Quality Materials: We use premium electrical steel, copper windings, and advanced insulation for superior transformer performance.

✅ Industry Expertise: Our team of engineers designs solutions tailored to the unique demands of various industries.

✅ Customization Options: We offer specialized transformers for challenging applications, ensuring a perfect fit for your needs.

✅ Energy Efficiency Focus: Our designs prioritize reduced losses, lower energy consumption, and cost savings.

✅ Reliable Performance: Henka Power transformers are rigorously tested to ensure they meet the toughest performance and safety standards.

Conclusion

Choosing the right transformer requires careful consideration of voltage requirements, load capacity, environmental conditions, efficiency, and compliance with safety standards. A well-selected transformer ensures seamless power distribution, protects equipment from electrical disturbances, and contributes to energy savings.

At Henka Power, we provide expertly engineered transformers designed to meet the evolving needs of industrial, commercial, and utility applications. Whether you need a standard transformer or a custom-built solution, we are committed to delivering reliable and efficient power solutions.

Looking for the perfect transformer for your application? Contact Henka Power today to discuss your project and find the ideal power solution for your needs.